Astal Structures Private Limited

Products & Services

Discover our wide range of innovative and durable PEB products, from prefabricated structures to turnkey solutions

Our Expertise

Products & Services

Pre Engineered Building Systems

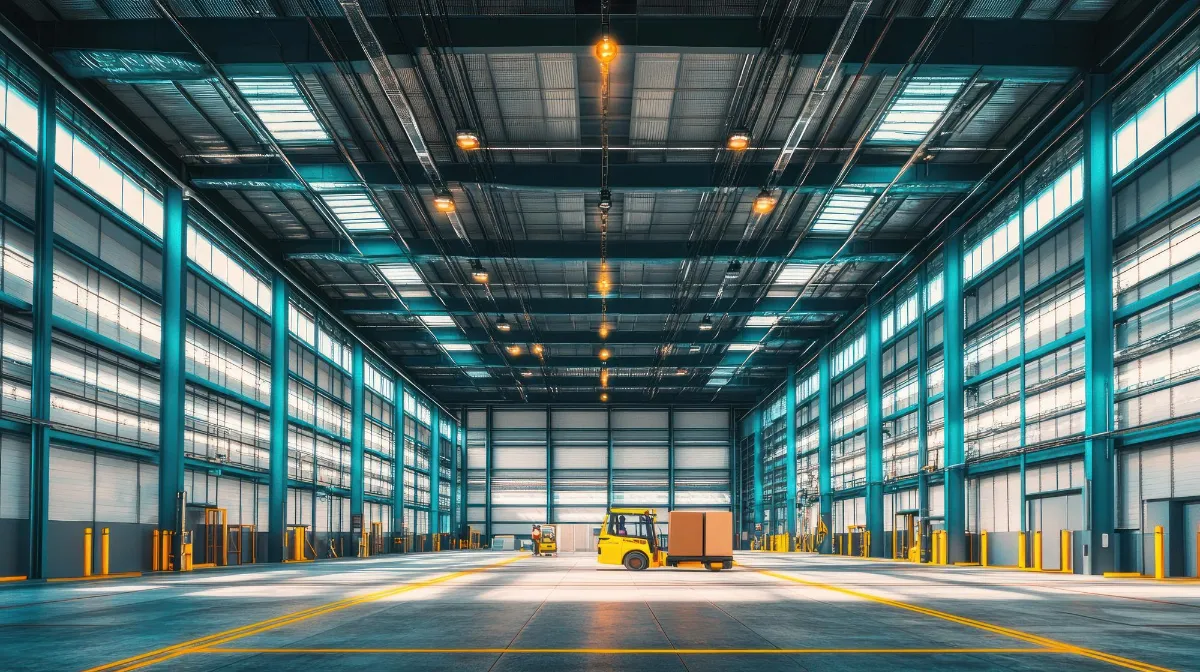

Astal Structures is a leading manufacturer of Pre-Engineered Buildings (PEBs), delivering end-to-end PEB solutions across industrial, commercial, and institutional sectors.

Our PEB steel buildings are engineered with precision, manufactured in a controlled factory environment, and tailored to suit specific operational requirements.

Using advanced design and prefabrication methods, every structure is produced with consistent quality, accurate detailing, and full compatibility across all building components. Once fabricated, the components are shipped to the site with clear identification as per erection drawings, enabling quick, streamlined assembly and minimizing on-site work.

With flexible design options, faster construction cycles, and long-term durability, Astal Structures provides dependable, high-performance steel building solutions that support efficiency and growth across a wide range of applications.

What is a Pre-Engineered Building (PEB)?

Our PEB steel buildings are engineered with precision, manufactured in a controlled factory environment, and tailored to suit specific operational requirements.

Using advanced design and prefabrication methods, every structure is produced with consistent quality, accurate detailing, and full compatibility across all building components. Once fabricated, the components are shipped to the site with clear identification as per erection drawings, enabling quick, streamlined assembly and minimizing on-site work.

With flexible design options, faster construction cycles, and long-term durability, Astal Structures provides dependable, high-performance steel building solutions that support efficiency and growth across a wide range of applications.

Core Components of a PEB

Primary Frame System

The primary frame is the backbone of a PEB structure. It is constructed using I-beams or tapered built-up sections, which are specially engineered to carry the entire building’s vertical and horizontal loads. These include dead loads (weight of the structure itself), live loads (occupants, equipment), and environmental forces like wind and snow.

Each element—columns and rafters—is designed using advanced CAD and structural analysis software to ensure:

- Maximum load-bearing strength

- Material optimization for reduced cost

- Customization based on span, height, and roof pitch

The primary framing provides the skeletal support needed to hold up the roof, sidewalls, and attached components securely.

Types of Standard Frame

Tapered Column Clear Span

Multi Span I

Multi Span II

Multi Span III

Lean To

Multi Gable (MG) I / II

Clear Span with Crane (Bracket & Beam)

Mono Slope

Rafter System

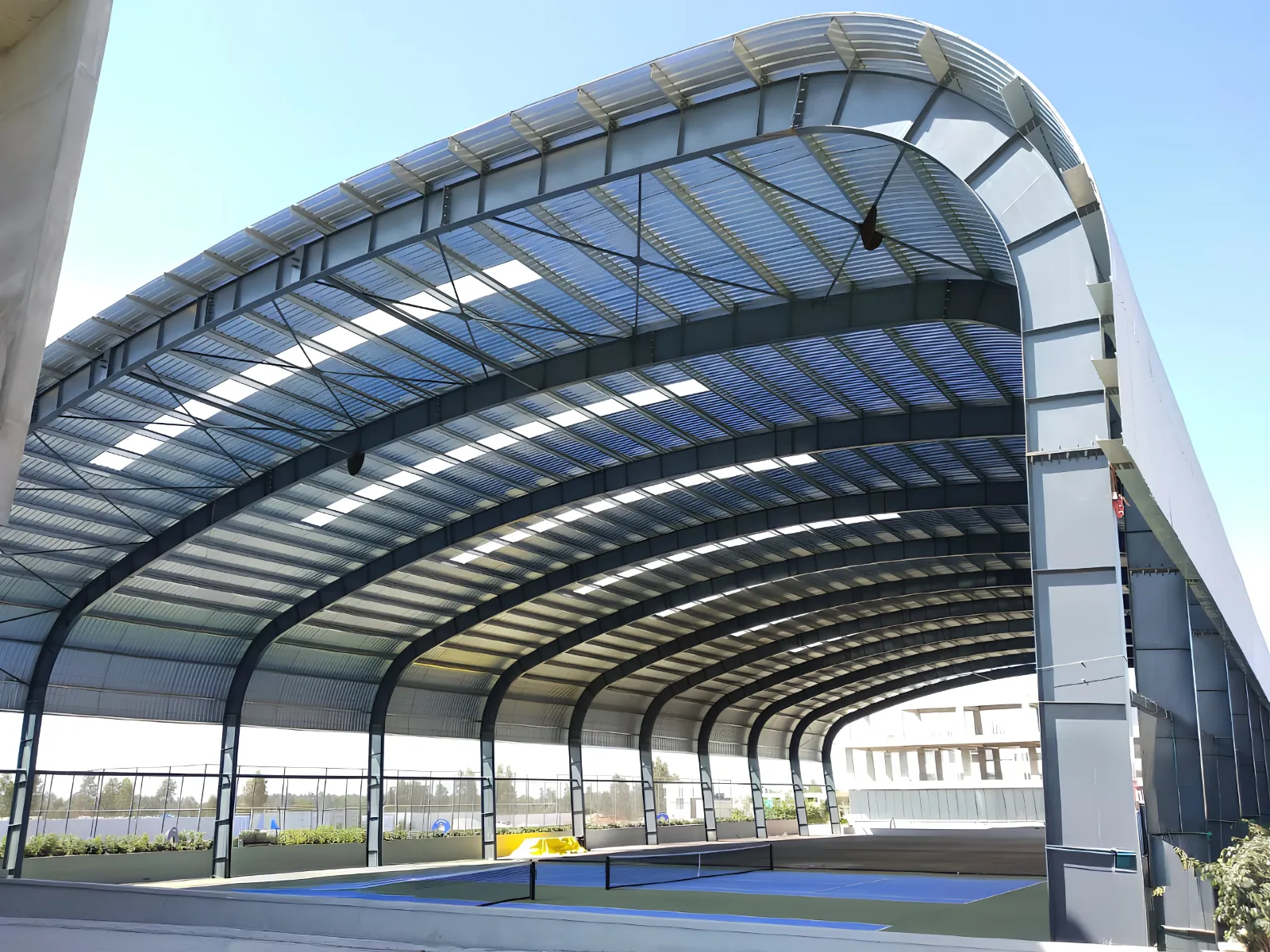

Builtup Curved Frame

Arched Multi Span

Multi Span I with Crane (Bracket | Beam) & Mezzannine

Secondary Members

The secondary framing system supports the overall stability of the structure and helps distribute loads from the roofing and walls to the primary frame. These members include:

- Purlins: Horizontal beams supporting the roof sheets

- Girts: Horizontal beams attached to wall cladding

- Eave struts: Positioned at the roof and wall junction, providing support and shape

These components:

- Provide lateral support to prevent buckling of the primary frame

- Act as fixing points for roof and wall panels

- Improve the overall rigidity and durability of the structure

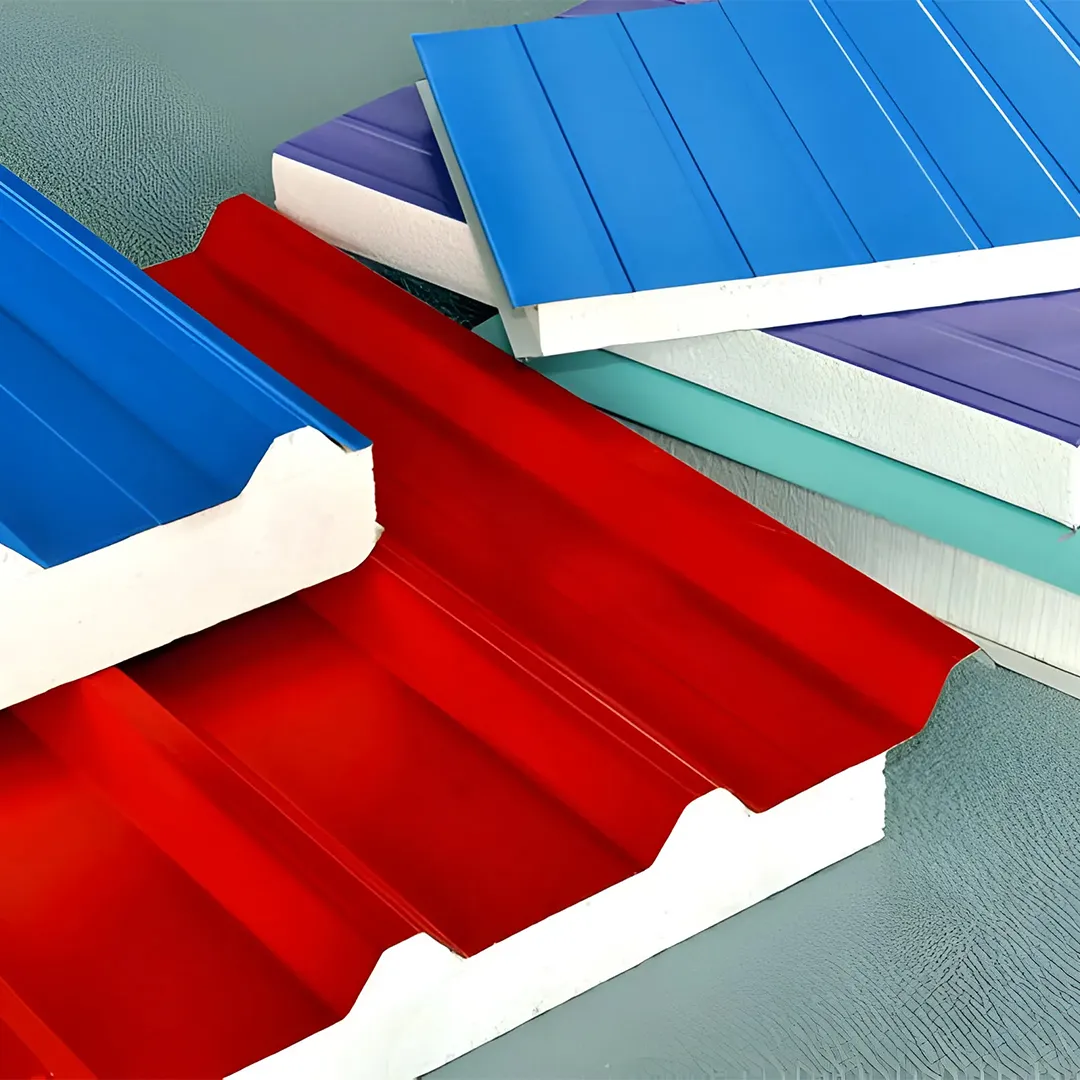

Roofing and Cladding

Roof and wall panels in a PEB are made from high-quality materials like galvanized steel sheets, color-coated panels, or sandwich panels (with insulation cores like EPS or PU). These serve as the building’s envelope, protecting it from external elements.

Advantages of PEB roofing and cladding:

- Corrosion resistance due to protective coatings

- Thermal insulation (in the case of sandwich panels)

- Lightweight, reducing structural load

- Quick and easy installation, reducing construction time

Accessories

PEBs are highly versatile and can be customized with a wide range of accessories to enhance functionality, comfort, and operational efficiency. These include:

- Skylights – for natural lighting

- Turbo ventilators and ridge vents – for airflow and temperature control

- Canopies and overhangs – for weather protection at entry points

- Mezzanine floors – for office space or storage within the building

- Rainwater gutters and downspouts – for drainage and water management

- Doors, windows, and louvers – for utility access and air circulation

These elements are pre-fabricated and installed during the erection process, ensuring smooth integration into the overall structure.

Advantages Of PEB (Pre-Engineered Building)

Faster Construction Time

PEBs are fabricated in a controlled factory setup using pre-designed and pre-cut components, which makes on-site assembly quick and efficient. With minimal labor and streamlined installation, projects can be completed up to 50 percent faster than conventional concrete or brick structures — a huge advantage for time-sensitive operations and rapid expansions.

Cost-Effective

Precise fabrication reduces material waste, while faster assembly lowers labor and overhead costs. Shorter timelines also cut financing and project management expenses. Since PEBs are lighter, they often require smaller foundations, adding further savings. Altogether, they deliver strong long-term value and higher ROI for industrial and commercial users.

High Strength-to-Weight Ratio

Steel’s impressive strength-to-weight ratio allows PEBs to support large spans without internal columns, ideal for warehouses, showrooms, and industrial units. The lighter structure reduces foundation loads while still offering strong resistance to wind, seismic forces, and other environmental stresses.

Minimal Maintenance

PEBs need very little upkeep thanks to corrosion-resistant coatings, termite-proof materials, and fire-resistant finishes. Roofing and cladding systems are built for long-term durability, often backed by warranties of 15–25 years. Routine inspections and occasional touch-ups are usually all that’s required.

Eco-Friendly Construction

Off-site fabrication cuts down site disturbance and reduces construction waste. Steel — the main material — is recyclable and supports sustainable design. PEBs also make it easy to integrate green features like solar panels, rainwater harvesting, and high-efficiency insulation, further reducing environmental impact.

Flexible Expansion

PEBs are modular, making future growth simple and cost-effective. Additional bays can be added horizontally, multi-story extensions can be planned in advance, and interiors can be reconfigured without major structural changes. This adaptability makes PEBs ideal for businesses expecting operational expansion.

Applications Of PEB Structures

Industrial

Sector

- Manufacturing units

- Warehouses

- Workshops

- Cold storage units

Commercial

Sector

- Malls and showrooms

- Office buildings

- Retail stores

- Exhibition centers

Institutional And

Infrastructure

- Schools and universities

- Airport terminals

- Sports complexes

- Railway stations

Residential Sector

(Modern Adoption)

- Villas with steel frames

- Modular housing units

- Workshops

- Farmhouses and weekend homes

Our PEB Process

Astal Structures follows a systematic approach from design to delivery:

Design & Engineering

Every building begins with structural calculations, load analysis, and detailed software-based planning to ensure safety and efficiency.

Factory Fabrication

Transportation & On-Site Erection

Labeled components are delivered to the site for quick assembly using bolted connections, minimizing welding and on-site labor.

Finishing & Customization

Why Choose Astal Structures

Astal Structures follows a systematic approach from design to delivery:

Manufacturing Expertise &

Capacity

Advanced fabrication facilities and experienced engineering teams.

Quality Standards &

Certifications

Rigorous quality control ensures reliable performance.

End-to-End

PEB Solutions

Comprehensive services from design and fabrication to delivery and erection.

Portfolio &

Client Satisfaction

Proven track record across industrial, commercial, and institutional projects.

FAQs

Astal Structures follows a systematic approach from design to delivery: